Mining Wire Rope, Attachments and Equipment

Complete mine hoisting solutions—including wire rope, attachments, equipment, and expert services—engineered for safety, performance, and reliability in the most demanding mining environments.

Capabilities

- Project Assessment

- Rope up & Rope Change

- Accident Remediation

- Consulting & Procedure Development

- Custom Fabrication & Machining

- Mining Wire Rope Supplying

- Conveyance Installation & Removal

- Wire Rope Spooling Service

Rentals

- Specialty Shaft Rigging

- Reel Stands

- Winders & Unwinders

- Tensioners

- Tuggers & Load Winches

Training

- Wire Rope Socketing

Spooling

- Equipment Operators

- Spare Reels

Mining Wire Rope

By working with customers in the mining industry since 1970, Northern Strands has provided products and technical expertise for some of the world’s most challenging and complex hoist installations. Regardless of the hoist configuration or the stage of mine development, Northern Strands provides a complete range of wire ropes.

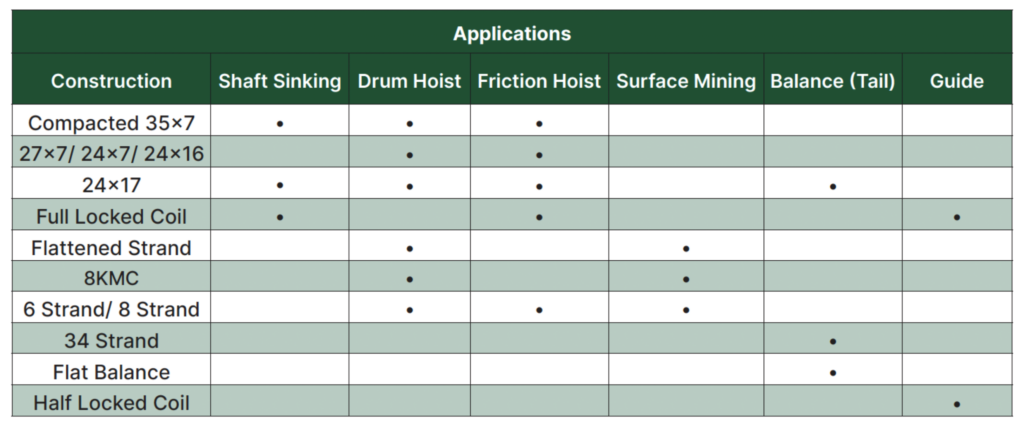

Mining wire rope applications

Friction (Koepe), Drum, and Blair Hoist Ropes

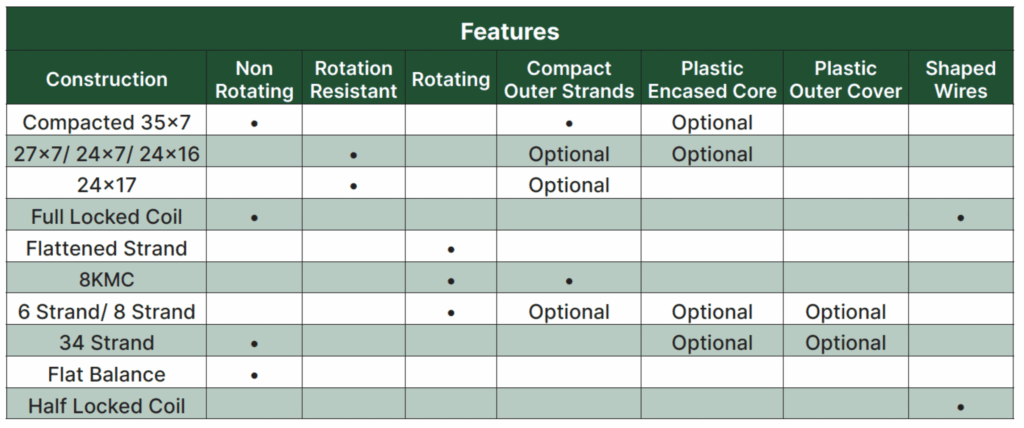

There are various wire rope constructions to consider for your hoisting operation, each with its own characteristics and advantages.

- 35×7 (multi-strand)

- 24×7

- 24×17 / 27×7 / 24×16

- Flattened Strand

- 8KMC

- 6 Strand or 8 Strand

- Full Lock Coil

Shaft Sinking Ropes

A rotation-resistant rope is required for sinking ropes. As the shaft gets deeper, the resistance to rotation becomes critical.

Slope Hoists & Surface Mining

Flattened Strand, 6 Strand, and 8 Strand are the most common varieties here. The number of wires, level of compaction, and inclusion of plastic are all part of the design process.

Balance (Tail) Ropes

If you have a Friction (Koepe) hoist and you need balance (or tail) ropes.

- 34×7 / 34×17 / 34×19; plastic outer cover and plastic filled valley

- Flat balance ropes

Guide Ropes

Half-lock coil ropes are the most common choice for Guide ropes. Full-lock coil ropes are also considered in certain situations.

Rope Features & Options

Rotation in Wire Rope

Rotation-resistant rope is defined as rope designed to generate reduced levels of torque and rotation when loaded. It is designed with two or more layers of strands laid helically around the center, with the lay of the outer strands opposite that of the underlying layer. However, there are different levels of rotation resistance to consider.

Non-Rotating ropes can be used with swivels and have at least 15 outer strands and at least 3 layers of strands. Rotation Resistant rope have at least 10 outer strands and two or more layers of strands. Spin Resistant ropes have 9 outer strands or less and two layers of strands

Rope Finishes

Bright steel ropes are recommended for dry environments, while galvanized wire ropes are recommended for wet climates. Wires coated in an aluminum-zinc alloy (Galfan) are the best choice for corrosive environments.

Compacted Strands

Many of our hoist and sinking ropes come with compacted strands on the outer, inner, or all layers. Compaction can be customized to meet specific requirements. When compared to round strands with the same diameter, compacted strands have:

higher metallic area, higher MBS, added resistance to side pressure, wear, and abrasion, better spooling and resistance to crushing.

Plastic Encased Core

In hoist ropes with plastic-encased cores, a plastic sheathing is inserted between the outer and inner layers of strands. This plastic filler reduces the potential sliding of the various components while still allowing necessary movement. The plastic also fills the free space between the exterior strands, preventing friction and wear damage. The most significant advantage of this product is its ability to seal the lubrication in the inner strands and keep out the polluting agents that lead to corrosion.

Lubrication

Proper lubrication of wire rope is crucial during manufacturing, installation, and ongoing maintenance. Different hoists and applications necessitate specific types of lubrication. Northern Strands has the expertise to recommend and provide suitable lubrication products and advise on the most effective lubrication methods.

Wire Rope Lubrication Systems

Northern Strands is the North American distributor of CoreLube wire rope lubrication equipment and cleaners.

Mining Wire Rope Attachments & Equipment

Northern Strands offers a wide range of attachments for all mining ropes, along with an extensive inventory of installation equipment available for purchase or rental. Northern Strands also offers installation crews and consulting services to assist throughout the entire project. All attachments are designed and engineered to meet national coal board standards and local government regulations governed by ISO 9001.

Northern Strands attachments are manufactured to a high-quality standard with product serialization used for tracking and quality control through an advanced quality management system. All attachments are designed with a minimum 10:1 factor of safety, proof load tested to 2.5 times the safe working load, and undergo ultrasonic and wet magnetic particle inspections. They also come complete with test certificates and relevant QA/QC documents. Additionally, all attachments are available with or without wear bushings made in metallic or synthetic material.

Northern Strands Provides:

- Customizable Dimensions

- Complete Certification

- Quick Delivery

- Design

- New Installation

- Replacement

- Upgrades

- Recertification and Testing

- Modification

Hoist Rope Attachments

- Open Spelter Sockets

- Threaded Sockets

- Fine Adjustment Linkage

- Coarse Adjusting Linkage

- Wedge Type Cappels & Round Eye Cappels

- Chaseblocks & Link Plates

- Thimble Cappels

- Solid Thimbles

Balance Rope Attachments

- Sockets

- Swivels

- Chaseblocks & Pins

- Balance Rope (Short Loop) Cappels

- Solid Thimble & Clamps

Guide Rope Attachments

- Suspension And Maneuvering Glands

- Guide Rope Tensioning

- Guide Rope (Long Loop) Cappels

Shaft Sinking Attachments

- Dolly Ball

- Poured Socket

- Jaw & Tang Chaseblock

- Tang And Jaw Swivel

- Shaft Sinking Hooks

Specialty Equipment & Services

Installation & Reeving Equipment

- Socketing stands

- Deflection sheave assemblies with pedestals

- Double down sheaves

- Rope tensioner

- Reeving sockets

- Sheaves and pedestals

- D plates

- Maneuvering glands

- Suspension glands

- Safety blocks

- Safety clamps

- Gooseneck deflection sheaves

- Reel winder

- Wire rope shears (Hydraulic)

- Cappel banding press

- Snatch blocks

- Load Cells

- Electrical cable brackets

Maintenance Equipment

- Rope Lubrication Systems

- Rope Cleaners (Single & Multi Rope)

- Kellem Grips / Rope Grips

- Post-former

- Drum Liner Grooving Machines and Grooving Bits

Supplies

- Socketing resin

- Seizing wire

- Cleaners / degreasers

- Wire rope lubricants

Rope Person’s Tools

- Grooving tools

- Seizing machine

- Socketing tools

- Sheave groove gauges

- Rope calipers

- PFV coated rope repair kit

- Punch lok tools