Mining Services

Explore Northern Strands’ full range of mining services, including wire rope products, attachments, equipment rentals, training, and technical support.

Capabilities

- Fall Protection

- Rope up & rope change

- Supply mining ropes & attachments

- Conveyance rebuilds

- Conveyance replacements

- Recertification of attachments

On Site Training

- Wirelock Socketing Seminars

- Fall arrest

- Suspended Access

- Below the Hook Rigging

- Overhead Traveling Crane

Purchase/Rentals

- Specialty Shaft Rigging Equipment

- Spare Reels

NSGC as a complete Solution

Fortis is the dedicated service arm of Northern Strands, specializing in hoist installation and rope/conveyance handling. As an integral part of our operations, Fortis delivers expert field services with personnel and resources that ensure safety, compliance, and optimal performance across all projects.

By leveraging Fortis’ specialized capabilities, we provide a seamless, full-service solution from design through installation and maintenance.

OEM Support for Rope & Attachment Solutions

We provide comprehensive OEM support for rope and attachment sales, ensuring your systems are installed, commissioned, and supported to the highest standards. Our team offers end-to-end technical consulting, from product selection and system integration to on-site installation and commissioning.

With deep industry expertise and a commitment to operational excellence, we help clients maximize safety, performance, and reliability in every applicati

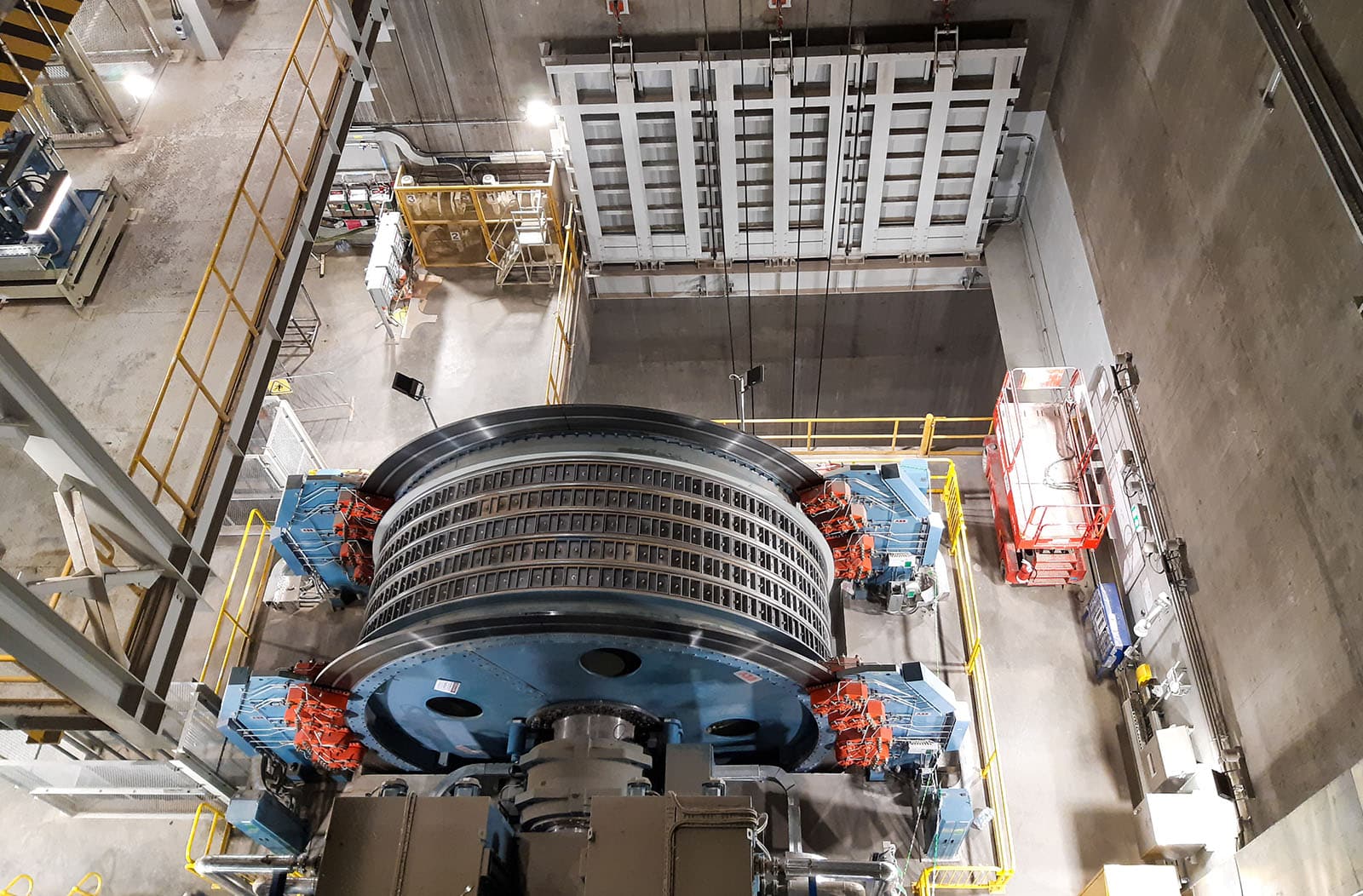

Hoist Engineering

We specialize in hoist engineering and deliver end-to-end services to support every phase of your hoisting system’s life cycle. From design and manufacturing support to installation, commissioning, and ongoing maintenance, our team ensures safe, efficient, and reliable hoisting operations.

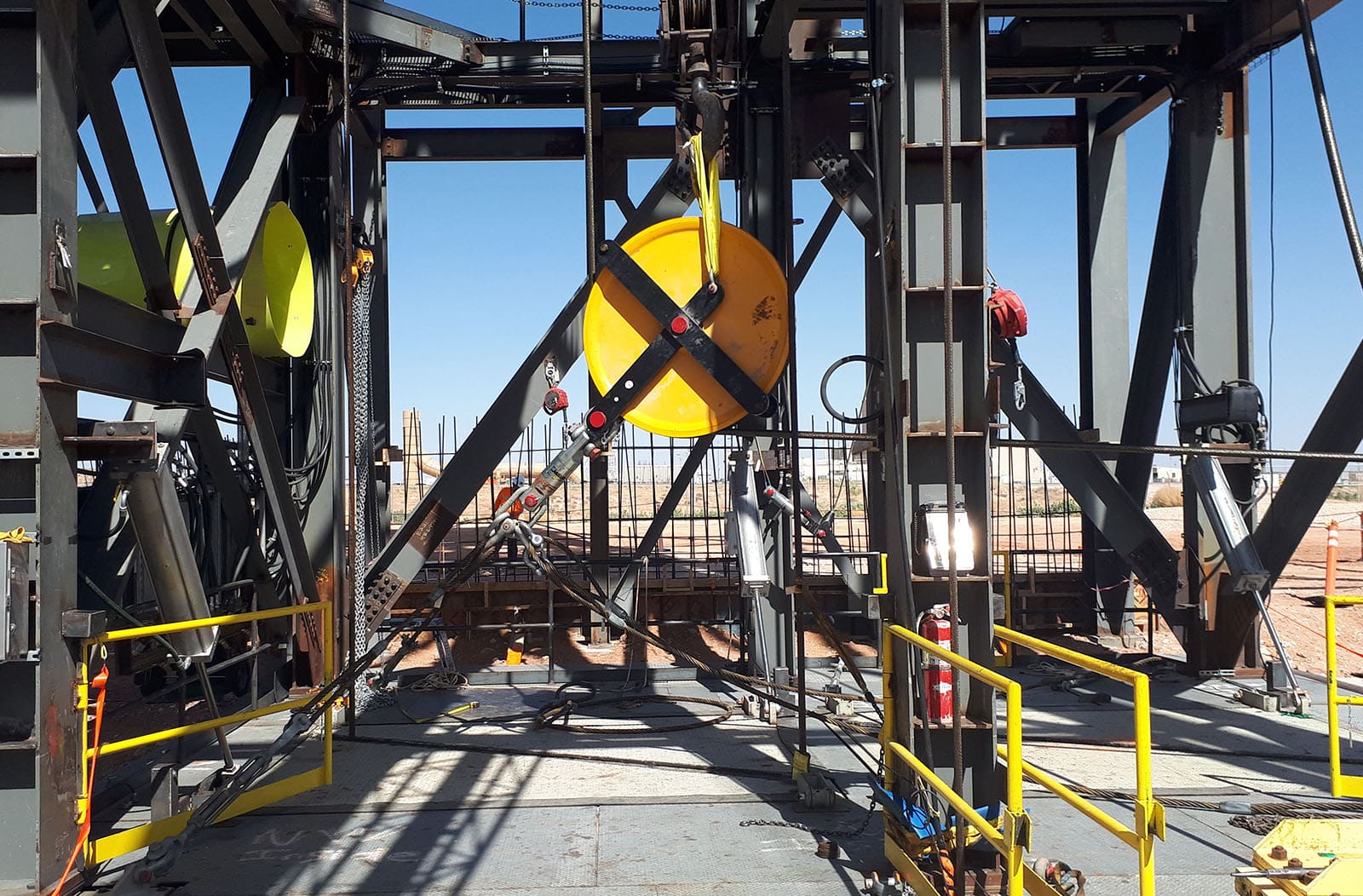

Rope Up Rope Change

We provide expert rope-up and rope change services to ensure safe, efficient, and compliant operations for all hoisting systems. Whether you’re installing new ropes or replacing worn ones, our experienced technicians follow strict OEM and regulatory standards to minimize downtime and maximize safety.

With a proven track record across diverse industrial environments, we deliver precision, reliability, and peace of mind every step of the way.

Related Projects

- International Shaft Sinking Rope Up

A client engaged Northern Strands Group of Companies (NSGC) to supply specialized rope tensioning equipment and qualified operators to support the rope up of their shaft sinking stage and service winches at a mine near Sydney, Australia. The NSGC team overcame the hurdles of overseas logistics, international work visas, and the 18-hour time difference. The rope-up of their shaft sinking winches was successful.

Shaft Rope–Up

Fortis has recently completed the successful rope-up of the production and service hoists internationally, which was completed ahead of schedule and under budget. The shaft consists of two tower-mounted Koepe hoists, which were roped up utilizing a Siemag Tecberg multi-rope friction winch and Clamping Lifting Device (CLD).

Shaft Rope And Skip Replacement

Fortis was contracted in the united states to complete a head rope replacement and skip replacement in a shaft during a long wall shutdown. Phase one of this project was to remove the four existing head ropes from their ground mounted hoist. This consisted of chairing the three balance ropes at the collar level on surface as well as banking the existing skip in the headframe.

Mine Specific Engineered Fall Protection

We design and deliver Engineered Fall Protection systems specifically for the demanding environments of the mining industry. Our solutions are tailored to protect workers at height—whether on headframes, platforms, conveyors, or shaft infrastructure—ensuring full compliance with safety standards and site-specific requirements. From concept to commissioning, our team provides complete support including system design, structural integration, certified installation, and ongoing inspections.

Design

Installs

Inspections

Supply

Shaft & Headframe

We provide engineered fall protection systems tailored for the unique challenges of shaft and headframe work environments. Our solutions include rigid rail systems, davits, and lifeline installations, all designed to ensure worker safety during vertical access, maintenance, and material handling tasks.

- Rigid rail

- Davits

- Lifelines

Loadout Facility

We deliver engineered fall protection solutions designed specifically for the high-risk environments of load-out facilities. Whether your operations involve rail, truck, or conveyor load-outs, our systems are custom-engineered to ensure safe access and mobility for personnel working at height.

Ore storage facility

Our engineered fall protection solutions are expertly designed to safeguard workers in the challenging environment of ore storage facilities. From elevated platforms and conveyors to stockpile access points, we deliver customized systems that ensure safe working conditions at height.

Mine Building Rooftops

We provide tailored engineered fall protection solutions for all types of buildings on mine sites, including administrative offices, processing plants, maintenance shops, and control rooms. Our systems are designed to protect personnel working on rooftops, elevated walkways, and service platforms—ensuring compliance with strict safety regulations.