Northern Strands was awarded the supply of ropes, attachments, wirelock and specialty equipment for the WIPP (Waste Isolation Pilot Plant) project in New Mexico.

The WIPP website describes the project as follows, "WIPP was constructed for disposal of defense-generated TRU waste from DOE sites around the country. TRU waste consists of clothing, tools, rags, residues, debris, soil and other items contaminated with small amounts of plutonium and other man-made radioactive elements. The waste is permanently disposed of in rooms mined in an underground salt bed layer over 2000 feet from the surface.

The $75 million shaft sinking is integral to increasing ventilation to the WIPP underground. When completed, it will be WIPP’s largest shaft at 26 feet in diameter, reaching 2,275 feet, with drifts, or passageways, being excavated at the 2,150-foot level to match the rest of the WIPP underground that will eventually connect to the shaft."

The scope of supply includes the sinking rope, stage rope, clam rope, and emergency hoist ropes along with all the shaft sinking rope attachments. Due to their wide range of capabilities, Northern Strands was also able to provide the sinking bucket chains, plumb bob lines, load cells, as well as specialty installation and maintenance equipment including maneuvering glands and a double down sheave.

Northern Strands supplies Mining Wire Rope, Attachments and specialized to tools for mines across the world.

Email: info@northernstrands.coom

Phone: 1-800-242-7073

There are new reduced prices on Northern Strands' Flattened Strand and Non-Rotating in a variety of diameters and lengths. Contact us for details on the reduced prices on Flattened Strand, Fiber Core, Galvanized, Poly Core, Non-Rotating, Compacted, Plastic Encased Core, and the many other constructions available!

To view the brochure with the Wire Ropes available, please click the following link: Wire Rope Reduced Prices.pdf (3MB)

Northern Strands has Saskatchewan's largest inventory of wire rope available. Northern Strands has a large selection of rigging products and is is a distributor for some of the largest world class manufacturers in the industry including The Crosby Group, Gunnebo Johnson, Thern, Unitex, Vitali International and more

3235 Millar AveSaskatoon SK S7K 573

306-242-7073

sales@northernstrands.com

In mining hoist ropes with plastic encased core, a plastic sheathing is inserted and impregnated between the outer layer of strands and the inner layer(s) of strands. This plastic filler reduces potential sliding of the various components while still allowing necessary movement. The plastic also fills the free space between the exterior strands which acts as a cushion and noticeably prevents friction wear damages. But perhaps the biggest advantage of this product is that the plastic covers the core, so it’s able to seal the lubrication in the inner strands and keep out the polluting agents that lead to corrosion.

Northern Strands carries all major types of mining wire rope and attachments.

The types of mining hoist ropes:

Sinking RopeHoist RopesBalance RopesGuide RopesSurface Ropes

The types of mining hoist rope attachments and hardware:Contact Northern Strands

Mining Wire Rope and Attachments division to learn more or visit our webpage

Phone 306-242-7073

Toll free 1-800-242-7073

Email info@northernstrands.com

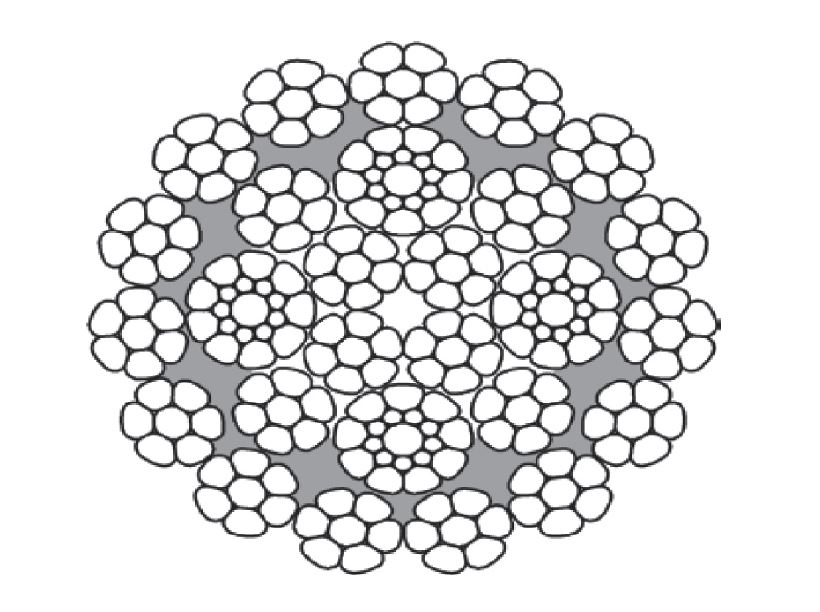

Picture: Compacted 35 X 7 Hoist Rope

Picture: Compacted 35 X 7 Hoist Rope

Northern Strands is excited to announce the release of our Mining Wire Rope Catalogue! Our catalogue contains detailed info on numerous types of mining ropes including hoisting, surface mining, balance and guide ropes. Plus, our catalogue offers descriptions of mining wire rope applications and features to help you pick the best wire rope for the job. It also informs the public of the top brands Northern Strands carries in wire rope lubricants, attachments and liners. Recently Northern Strands has become the North American supplier for Becorit hoist drum liners and the Canadian supplier for Corelube wire rope lubrication products.

Below is a downloadable PDF of our Mining Wire Rope Catalogue.

Northern Strands Mining Wire Rope Catalogue Email Version.pdf (6.24 mb)

The above PDF is a convenient email size, but is not a high resolution printable version. Email info@northernstrands.com to request a quality printed copy of our Mining Wire Rope Catalogue.

Watch for our Mining Wire Rope Attachments Catalogue that will be released in the near future.

To request information or a quote on Mining Wire Ropes please contact:

Les Nimmo

Mining Rope Technical Sales

Phone: 306-242-7073

Email: lnimmo@northernstrands.com

Northern Strands is proudly Saskatoon, Saskatchewan owned and operated

Rotation-resistant rope is defined as stranded rope designed to generate reduced levels of torque and rotation when loaded and comprised of two or more layers of strands laid helically around the center, with the direction of lay of the outers strands being opposite to that of the underlying layer. However, there are different levels of rotation resistance to consider.

Rotation-resistant rope (Category 1): Stranded rope constructed so that it displays little or no tendency to rotate, or, if guided, transmits little or no torque. It has at least 15 outer strands and is comprised of at least three layers of strands laid helically over a center in two operations, with the direction of lay of the outer strands being opposite to that of the underlying layer. This rope is also known as Non-Rotating.

Rotation-resistant rope (Category 2): Stranded rope constructed so that it has significant resistance to rotation. It has at least 10 outer strands and is comprised of two or more layers of strands laid helically over a center in two or three operations, with the direction of lay of the outer strands being opposite to that of the underlying layer. This rope is also known as Low Rotation.

Rotation-resistant rope (Category 3): Stranded rope constructed so that it has limited resistance to rotation. It has no more than 9 outer strands and is comprised of two layers of strands laid helically over a center in two operations, with the direction of lay of the outer strands being opposite to that of the underlying layer. This rope is also known as Spin Resistant.

Come back again in the near future for the next installment of Wire Rope Corner. Be safe out there.

Northern Strands Mining, Wire Rope, Attachments & Equipment Division excels by providing a wide range of equipment and services, by being the best full service provider of wire ropes, attachments, equipment and service. Truly Mine Hoisting Solutions®.

Northern Strands is proudly Saskatoon, Saskatchewan owned and operated.